R&D services

With our support you will realize your concepts and hopefully make the world a better place.

R&D services

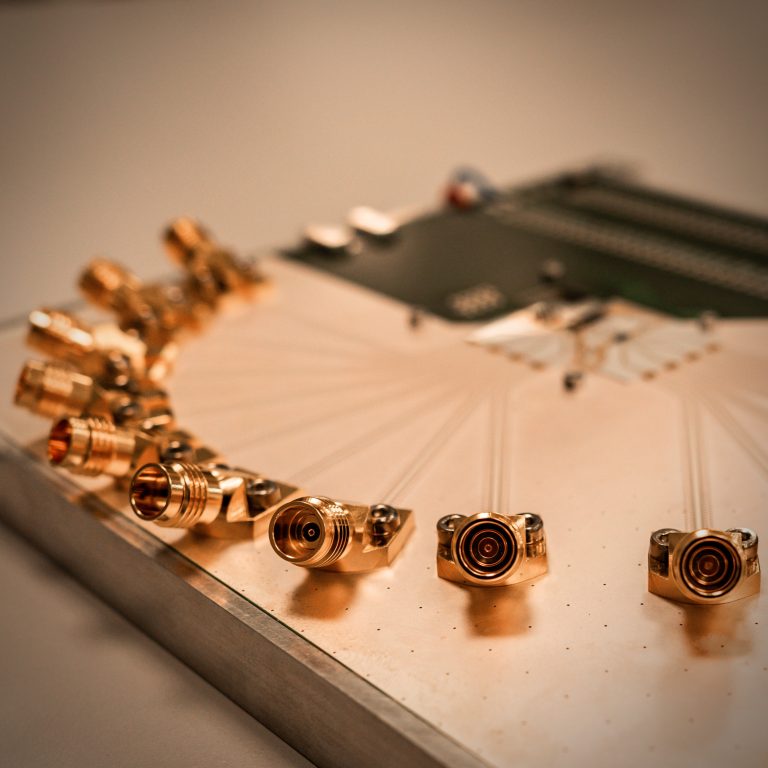

Our experienced team of development engineers can support partners with bridging the gaps in packaging area.

Regardless of the stage of your concept readiness, we can start with simulations and a feasibility study to prove the concept and recommend further steps to achieve the best parameters.

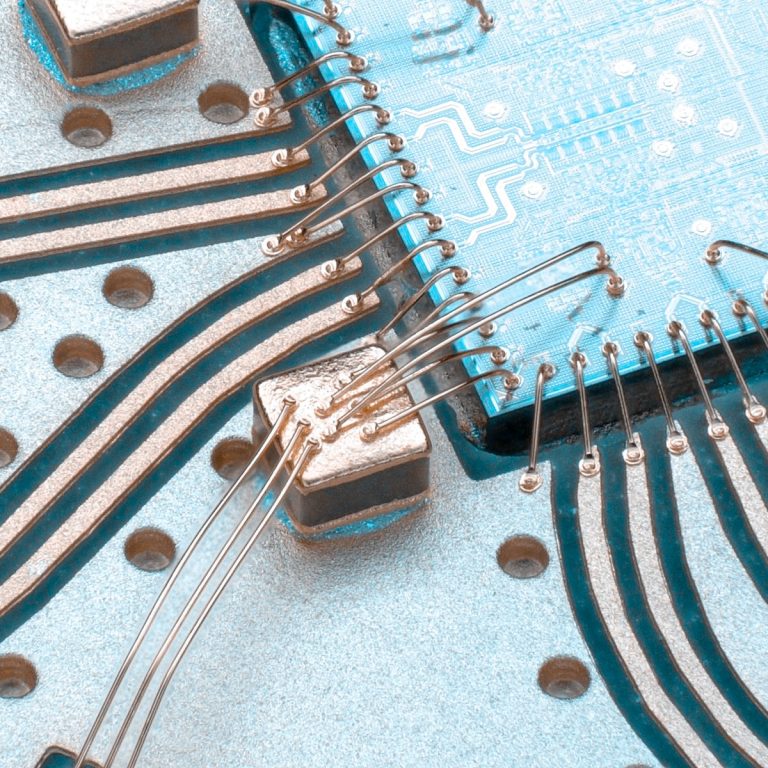

In addition we provide valuable feedback to front-end chip designers to enable their components to be further efficiently integrated into semiconductor packages.

We are here to support you with integration into any subsystems using any of available packaging platforms. We can help to bring your concept to the market.

We understand fully the development cycle of the product EVS – DVS – PVS.

We provide the following outputs based on project readiness level:

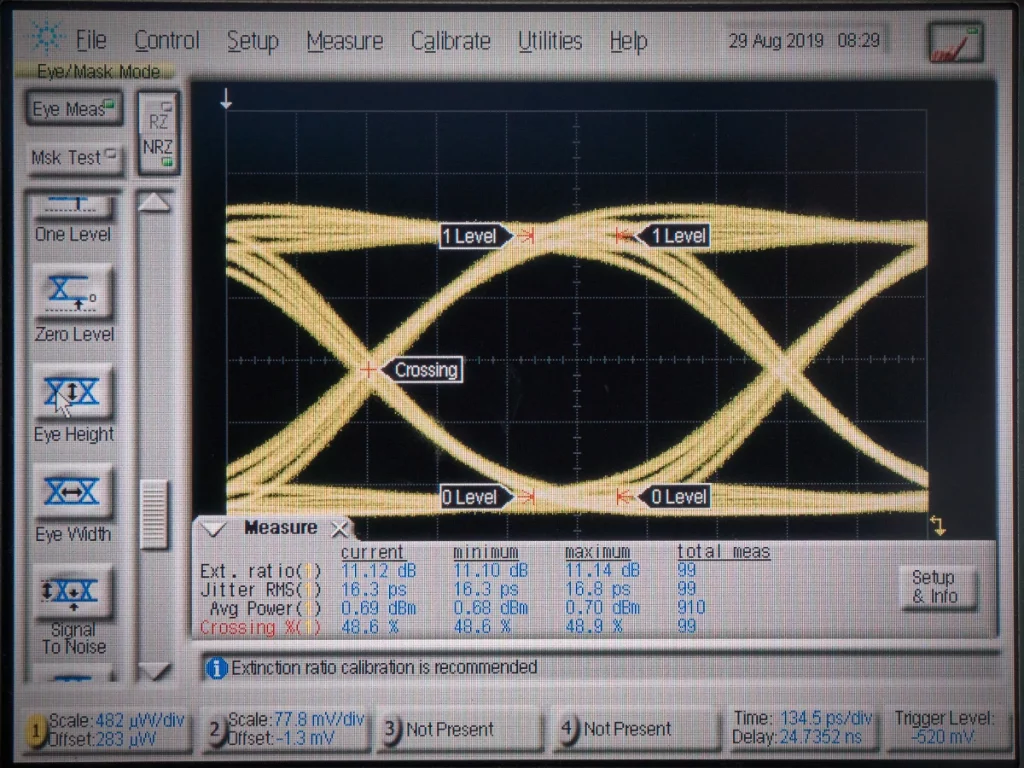

- Simulations – thermal, high frequency, optical, electrical, mechanical

- Feasibility study, proof of concept

- Design – mechanical and optical

- Prototype build – evaluation and qualification

- Assembly process development

- Sample batch verification

- Publicly funded projects

- Long-term R&D contracts

IF YOU HAVE

WE PROVIDE

GOOD IDEA

1

Feasibility study

It’s always better to start with Proof of Concept. We can help to decide if the idea is worth further investment or not.

PROOF OF CONCEPT OR

FEASIBILITY STUDY

2

Design proposal

Once you have a verified concept we help with design improvement considering all the related inputs, further packaging steps and your target requirements. The theoretical design is the output.

THEORETICAL DESIGN

3

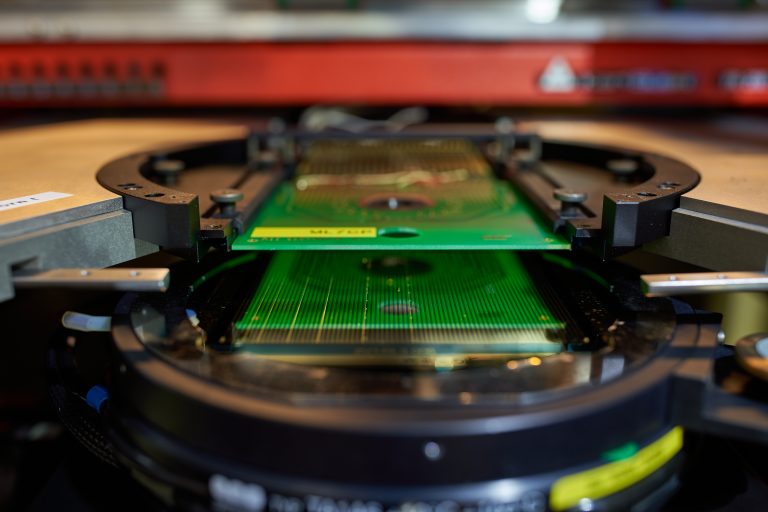

Prototype build

The theory must be verified. We first make an engineering verification sample (EVS) and the demonstrator. All the inputs including material, tools and equipment setting will be verified and tested.

PROTOTYPE

4

Sample batch, process set up

For larger testing and production process documentation, we set up the production process and make the first batch to verify the yield within requested parameters and repeatibility.

Sample Batch

5

Larger evaluation batch

To ensure the process stability and sustainability we recommend verifying all the inputs and processes within larger production batches. It results in process debugging and supplier chain verification.

BATCH PRODUCTION,

PROCESS TO MODIFY

6

Production process tuning

If the yield by the original vendor is not high enough or the process is unstable, we are able to support with process tuning and to propose process or design improvements.

Do you need more information?

We are ready to assist you. Contact us directly here and give us a brief description of your project. We will get back to you as soon as possible.

Our Services

and Technologies

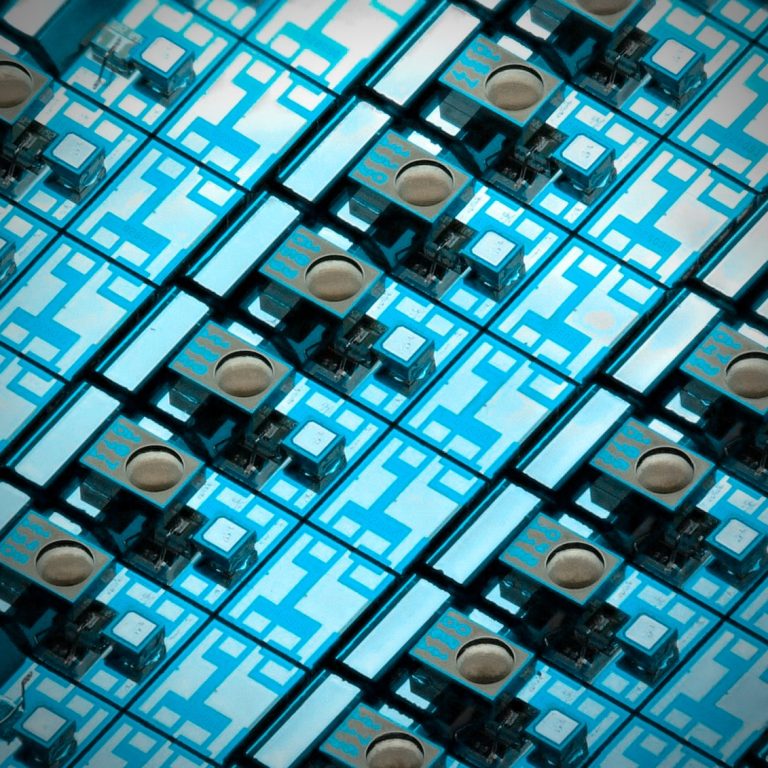

- Our technology can be used either as a complete assembly process or only partially.

- Take a look at our R&D capabilities, where we can bring your idea to life.

- We can provide Proof of Concept data on your prototype

to determine if it is worth improving. - We can offer characterisation and testing devices for your production or research and development if you lack these capabilities.

Manufacturing

- Flexible volumes

- CM/OEM/ODM

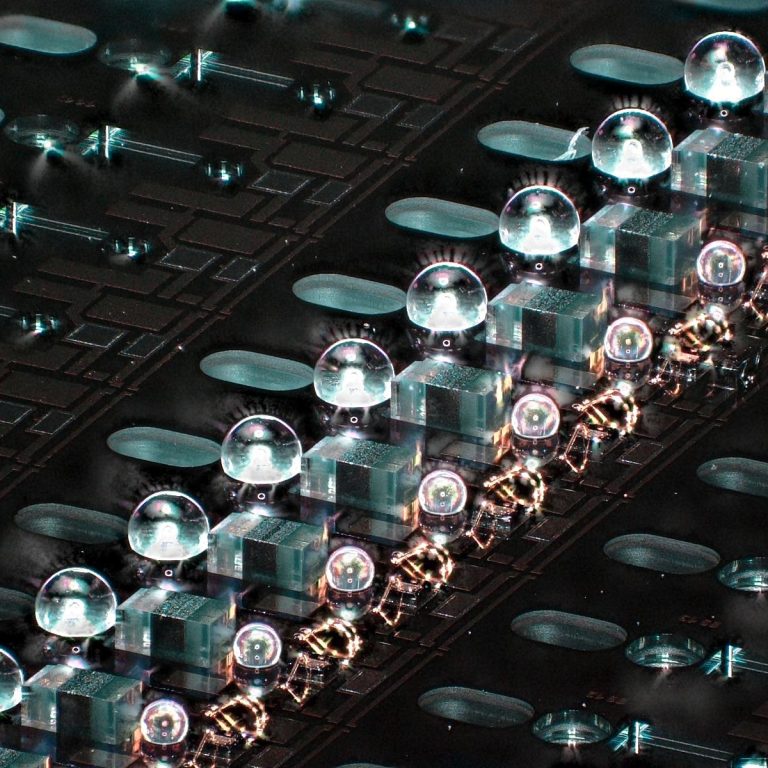

- UV to MIR applications

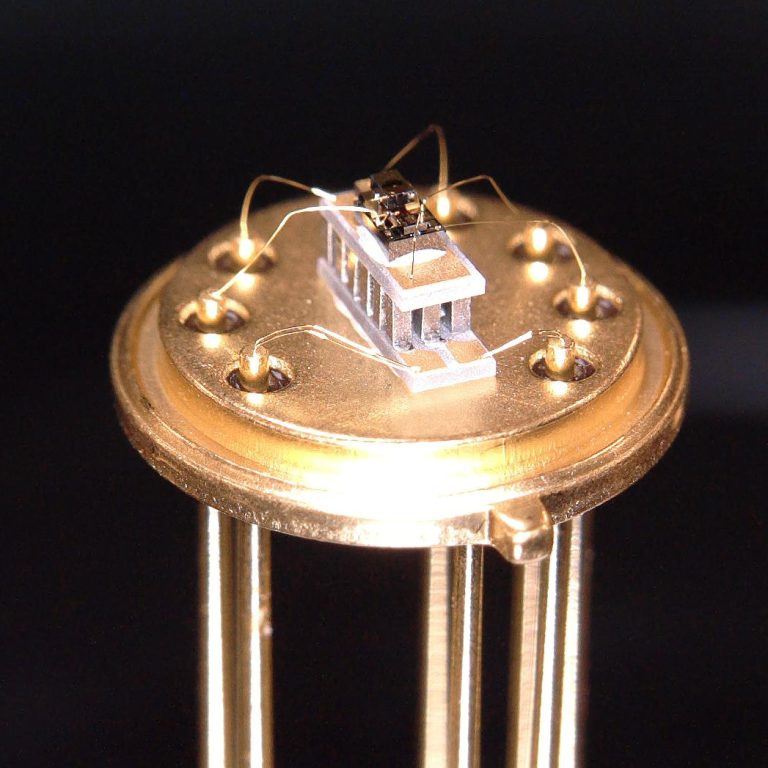

- SiPh into TO package

- Complex packaging solution

- WLA and die level assembly

- PFMEA/Traceability/SPC

- Production data management

R&D services

- Simulations

- Feasibility study

- Packaging design

- Prototype builds

- Assembly process development

- Sample batch evaluation

- Publicly funded projects

- Long-term R&D contracts

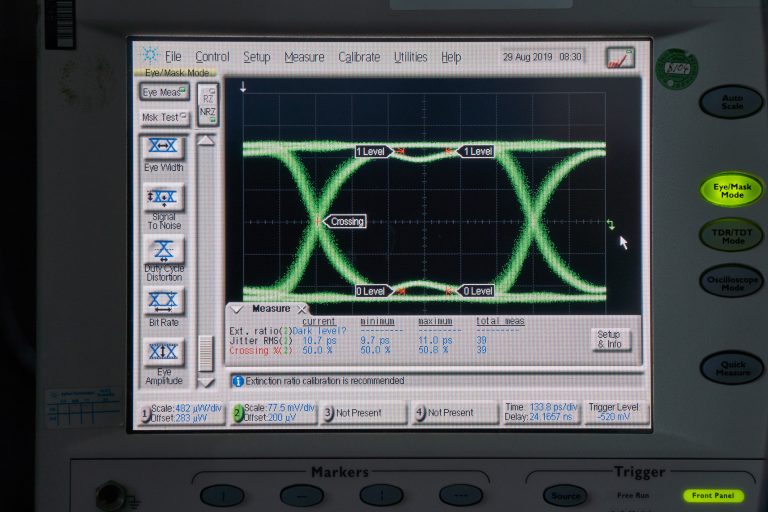

Testing services

- Characterization

- Qualification

- Burn-In

- Enviromental tests

- Shock temperature tests

- Accelerated ageing

- Selected standards compliance test

- Long term endurance tests